What is the name of an industrial gear unit that can be adapted precisely to the operating and ambient conditions of a particular application? CORRECT! Generation X.e! Individual and selective improvements to the hardware of our X series and a redesigned, networked calculation landscape are making this possible.

This is what makes the Generation X.e unique:

Generation X.e – efficient. experienced. excellent

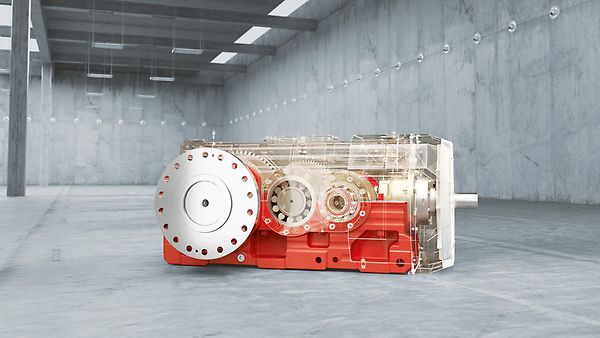

Description

Durability, finely graduated sizes, and an invertible housing are the characteristics of our tried and tested X-series industrial gear units.

The new Generation X.e is based on these features and impresses with its added efficiency, experience, and excellence: Because these industrial gear units can be adapted individually and precisely to the respective requirements of your particular application, both in terms of operation and the surroundings.

The result is:

- Highest possible efficiency

- Greater safety

- Longer service life, even in harsh conditions.

Technical data

| Gear unit design | Stages | Gear ratio i | Nominal torque MN2 kNm |

|---|---|---|---|

| Helical gear unit X.F.100e – X.F.250e |

2 to 4 stages | 6.3 – 400 | 6.8 – 175 |

| Bevel-helical gear unit X.K.100e – X.K.250e |

2 to 4 stages | 6.3 – 400 | 6.8 – 175 |

Applications

Conveyor belts, crane technology, mixers, crushers, and many more

- In mining

- In the cement industry

- In port logistics

What does a networked calculation landscape mean to you?

The new networked calculation landscape supports you perfectly with the selective configuration of your gear unit. Our industry experts assist you and can now take the highly specific operating conditions of your application into account.

Because the new Generation X.e has been enhanced precisely on the basis of the industry and application experience of both our experts and our customers from the fields of mining, cement, and port logistics. You too can take the consistent path toward ideal and highly efficient operating processes with our intelligent drive solution.

We'll be glad to assist you.

Do you have questions about our Generation X.e? Just fill in the form below and send us a message!